Golden Idea UV Varnishing

Varnish is a protective layer applied to product packaging. It is a liquid coating that is spread to the printing surface and then dried. The varnish creates an eye-catching appearance and polished look. What’s more? It provides suitable exterior protection.

Golden Idea makes custom-printed paper boxes in a variety of finishes available. It involves matte, glossy, and spot UV varnishing. The finishes can be applied to the full printed surface or on the required printed area.

Call us so we can discuss your options with you.

Varnishing Unique Benefits

- Printing ink dries more quickly.

- Rub-resistant – by keeping the ink under a layer.

- It guards against the ink rubbing off when the printed box is handled roughly.

- It gives the box surface a pleasing tactile sensation with a smooth and constant feel.

Types of Varnishing

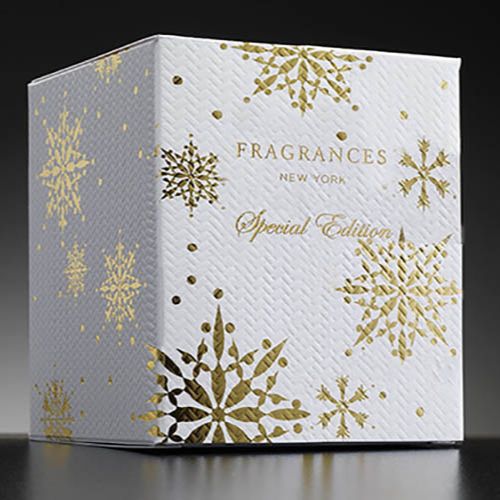

- Glossy Varnish – It provides a glossy, smooth, and shiny finish on the surface of the printed box. Effectively reflects light in the sun resulting in exceptionally bright and lustrous colors.

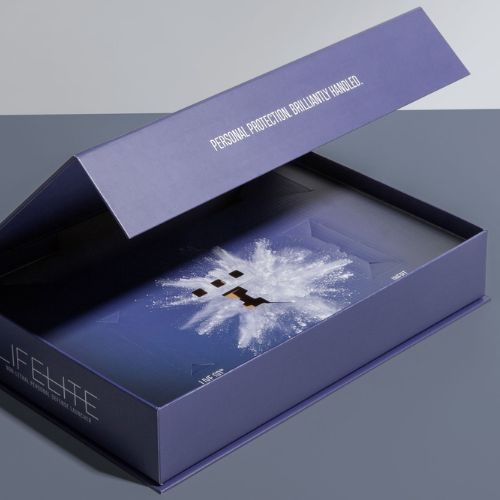

- Matte Varnish – It provides a non-glossy, even, and shine-free surface. Heightens the sense of luxury. Popular finishes are used in cosmetic and jewelry packing boxes.

- Satin Varnish – It offers the printed box surface a middle-ground appearance, neither high gloss nor matt.

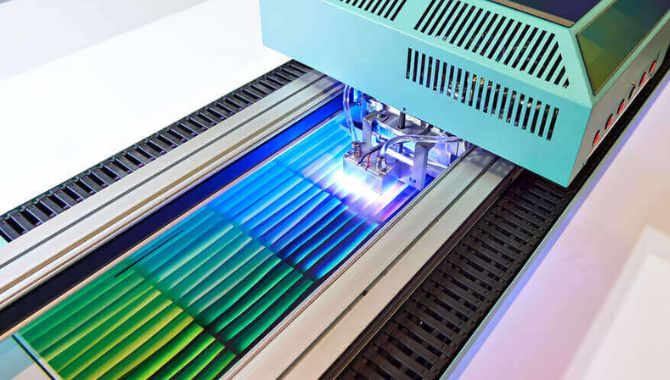

Application of Varnishing

UV varnishing is extensively used in different paper boxes, including:

- Printed paper box

- Printed corrugated boxes

- Rigid paper boxes

- Skincare packaging

- Cosmetic packaging box, etc.

3 Functions of Coating and Varnishing

1. Improved defense against stains, smudges, fingerprints, scratches, etc. for the inks.

2. The printing surface of the box can be coated to make it scratch-resistant.

3. Add a glossy or matte finish to the box to make it appear beautiful and eye-catching.

Protective Coating Options for Printed Boxes

Essentially translucent inks without a pigment

They are used as the standard CMYK inks.

The least expensive choice of all coating options

Water-based coating of 30-40% water content

It doesn’t produce VOC emissions which makes it eco-friendly

It has the benefit of using less powder on the printing press

Offers the highest shine and is abrasion-resistant

Starts from a clear liquid, then immediately cure when exposed to UV light.

Popular use to highlight the business logos.