Custom Paper Packaging Printing and Finish

At Golden Idea, we take great pride in offering superior printing services. We utilize the latest printing technologies and employ an experienced team of professionals who have the expertise to produce excellent-quality printing results. Our staff can help you in choosing the perfect printing process to fit your requirements. We are committed to delivering superior quality services and exceptional customer service to ensure that your printing project is completed on time and on budget.

Printing Techniques

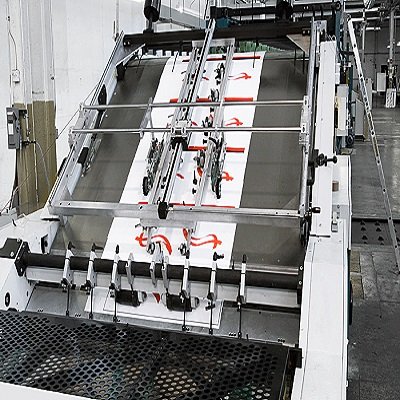

Offset printing produces superior quality and more vibrant print than digital printing, making it ideal for packaging boxes. It can create more complex and eye-catching designs. The colors are more consistent and the graphics are sharper. Offset printing also offers the advantage of a wider range of colors than digital printing.

Litho-lamination is a popular finishing process for paper packaging boxes and other printed materials. It is a process of applying a thin plastic film and a layer of adhesive to the surface of the paper. Creates a glossy finish and gives the printed material extra protection from water, dirt, and other environmental factors.

Flexo printing is a popular printing technique used for paper packaging boxes. It is a digital printing technology that uses a flexible printing plate to transfer an image onto a variety of substrates, including paper, corrugated cardboard, and plastic. Flexo printing is often used for printing logos, product information, barcodes, and other graphics on paper packaging boxes.

Silk screen printing is a great option for paper packaging boxes. It creates a smooth and even finishes that are perfect for displaying logos, text, and images. Silk screen printing offers a cost-effective solution for printing in large quantities and can be used for a variety of materials. Offers a vibrant and long-lasting finish that is perfect for product packaging.

UV printing is a common method used to decorate paper packaging boxes. This method can be used to create vibrant, crisp, and detailed images that have a glossy finish. The inks used for UV printing are specially formulated for this printing technique and can produce extremely durable and eye-catching results. Additionally, UV printing is a great choice for printing on a variety of materials, including cardboard, corrugated cardboard, etc.

Digital printing allows for high–quality, full–color printing on a range of paper types, including paperboard, corrugated, and kraft. It also offers quick turnaround times and low costs, making it an ideal solution for short–run and custom–printed paper packaging boxes.

Finish Options

Provides a glossy, waterproof surface that is more durable than untreated paper. It also makes the box look more professional and attractive.

Varnishing reduces the cost of production as it increases the durability of the box and prevents it from getting scratched or damaged. Additionally, varnishing can add a subtle sheen to the box, providing an eye-catching finish.

UV varnishing adds a glossy, protective finish to the box. It makes the box look more luxurious and giving it a longer lifespan. This finish helps to protect the printed graphics and text from fading, smudging, and scratching. A cost-effective way to enhance the look and feel of the box and make it more durable.

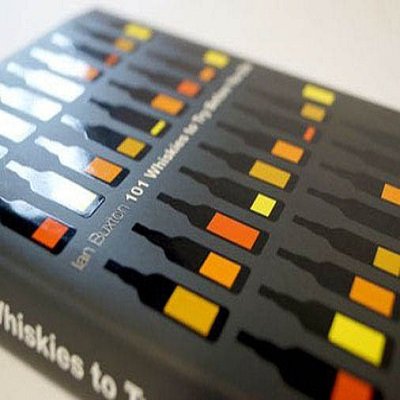

Applied to printed products to create a shiny, glossy look. It can add a unique look to the box, making it stand out from the rest. The spot UV finish can also be used to highlight certain areas of the box, such as the logo or branding, making those elements more visible and noticeable.

Create a series of small holes along the edges of the box. Perforation helps to make the box easier to open, as well as providing a more secure closure. Often used on boxes that need to be opened and closed multiple times.

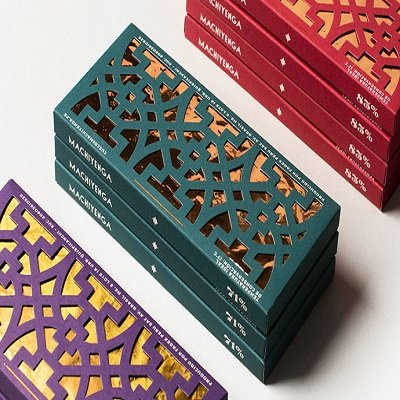

The embossing finish on a paper packaging box can give it a unique texture and a raised design that stands out from the surface of the box. This can add dimension and texture to the box, making it appear more luxurious and high-end. Embossing can also make the box more durable and resistant to scratches, wear and tear.

Foil stamping is a great way to give your paper packaging a luxurious, eye-catching look. The process involves a special foil being heated and pressed onto the paper surface to create a design, such as a logo or text. The finish is a metallic, glossy look that adds an extra level of sophistication to the box.

Die cutting involves cutting shapes, patterns, and other intricate designs into the material to create a unique and attractive look. Die-cutting can be used to create windows, slits, slots, and other shapes that can be used to display the product inside the box or to create a unique design.

Aqueous coating can provide a glossy, protective finish for paper packaging boxes. It is a water-based coating that dries quickly and provides a durable layer of protection against dirt, dust, fingerprints, and other contaminants.