Corrugated Board

Golden Idea is a leading provider of corrugated board bases in China. We supply different types of corrugated boxes that are made of front surface liner boards, corrugated fluting, and back surface liner board. It is perfect especially when needs more durable, high-strength, and printed folding boxes. our corrugated materials are perfect for making cartons, shipping boxes, mailer boxes, and more.

We can provide custom corrugated boxes of various sizes, thicknesses, and qualities. It is perfect for your custom corrugated display boxes, die-cut boxes, corrugated tray, and other types of boxes.

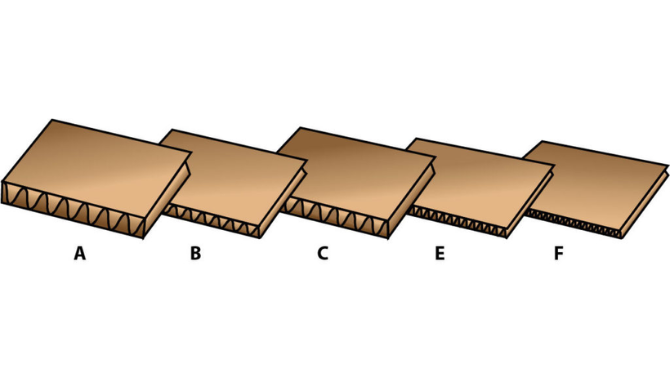

Common Medium Fluting Profiles and Sizes of Corrugated Board

Fluting is are made using semi-chemical flouting, and waste base floating to build up its properties. We have different common flute profiles and sizes to offer including:

- A FLUTE. It is good for stacking and for better protection. It is available in 5mm sizes.

- B FLUTE. It offers good puncture resistance and is known as the most common grade. It has a size of 3mm.

- C FLUTE. These are very common grades of corrugated boxes. The size of this is available in 4mm.

- E FLUTE. It is a lightweight fine flute due to its size of 1.2mm

- F FLUTE. extra thin type of flute due to its size of 0.9mm

- Aside from that, we have also EE FLUTE has a size of 4mm, EF FLUTE has a size of 3mm and BC FLUTE which has a size of 6mm.

Micro Flute Corrugated Box and Board

Aside from the medium flute, we have a micro flute. This micro flute refers to the following:

- E FLUTE

- F FLUTE

- G FLUTE

- N FLUTE

- O FLUTE

Every micro flute corrugated boxes are more lightweight than other boxes. It is perfect for packing, storage boxes, and shipping. This also offers excellent printability, easy to fold and cut and offers better durability and rigidity compared to other materials.

Linerboards

Aside from corrugated, we have a liner board. The liner board is commonly made from recycled pulp known as test liner, and virgin pulp called kraft liners. It is used for the outer part of corrugated boxes. Its designs provide a color tone and good strength. Due to it having a brown color and when printing process is needed, you can replace this with white lined chipboards. It has a white coating which very perfect for printing. There is various grammage of liner board such as:

- 120gsm

- 140gsm

- 170gsm

- 200gsm

- 230gsm and so on.

Different Testing Process of Corrugated boxes

We are doing different testing processes in order to provide you a quality corrugated boxes. Below is the common test we are doing:

- Strength test. We do strength depending on the materials used. In this process, we rest assured that every corrugated box can handle any pressure, can be resistant to bending, and is able to stand in harsh environments.

- Mullen Burst test. It is a process of measuring the force of a corrugated board from pound per square end (PSI). We make sure in this test that the corrugated box can be used for product shipping, storing products, and distribution. Meaning that this process explains wherein the higher number the stronger the corrugated box.

- Edge Crust Test. This is to test and measure the edge of corrugated boards. It is done by compressing the section of the boards with two rigid patterns. This process is very useful to make sure the box can withstand crushing.