What is Aqueous Coating?

The AQ coating is a process that uses to protect the print surface of the packaging box to become durable and strong. This can prevent any problem on the printed surface from shipping, rough handling, scuffing, and more. It is known as a water-based coating the same as a varnish coating.

Even though it is not very common and much more expensive than Spot UV. You really need this when it comes to providing high sharpness on the print color of the box.

Application of Aqueous Coating

Golden Idea offers this process of coating to meet the demand application for various industries such as:

- Retail packaging box

- Electronics packaging box

- Cosmetic packaging box

- Jewelry packaging box and more.

Advantages of AQ Coating

The AQ coating can shorten turn-around time which is very useful for short-running printing. This coating process provides excellent advantages such as:

- Environmentally friendly. This is the coating process which more eco-friendly than varnish coating.

- Yellow resistant. It is perfect especially if you need quality printing. It can prevent print become yellow. Also, it helps to remain the color print the same even for a long period of time.

- Fast drying. It is easy to very easy to dry unlike other coating processes. Meaning it can save production time.

Types of Aqueous Coating

There are two types of aqueous coating that design to give an attractive look to a packaging box. It is very important, especially on business brands, logos, etc.

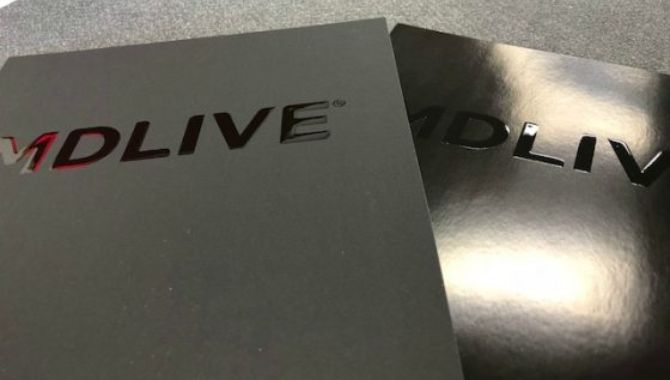

This type of aqueous coating is the same as glossy varnishing. It makes all custom paper box becomes:

- Shiny

- Glossy

- Have a Smooth look

This type of AQ coating are designed to add a matte look, especially on the outside of a paper packaging box. It is the same with matte varnishing which can:

- Soften the printed box

- Flattens

- To give luxury looks